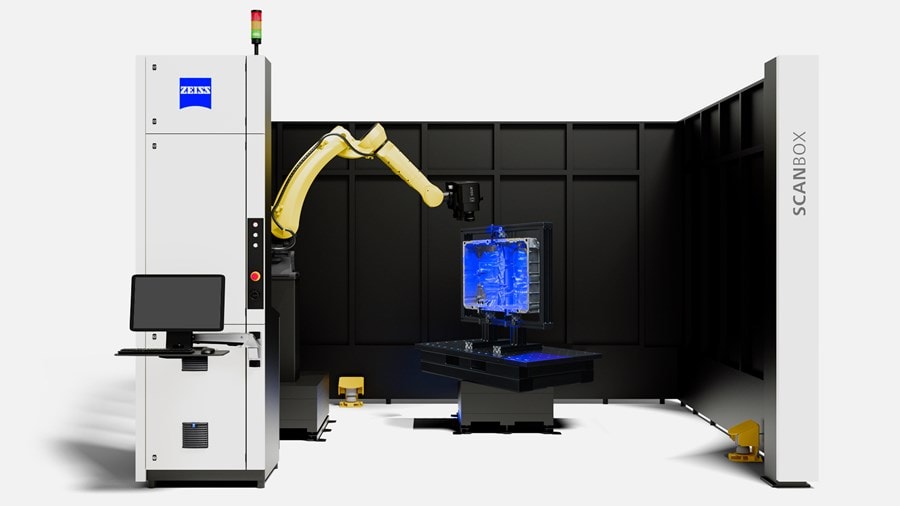

Fast. Precise. Modular

ZEISS ScanBox Series 5 is an all-in solution for automated inspection and digitization of complex parts. The series consists of three models and offers many options for customizing to your needs – that’s what we call the new modularity. The individual components are identical and therefore offer perfect possibilities for upgrading to different layouts. The maximum load of the rotation table module is 2000 kg.

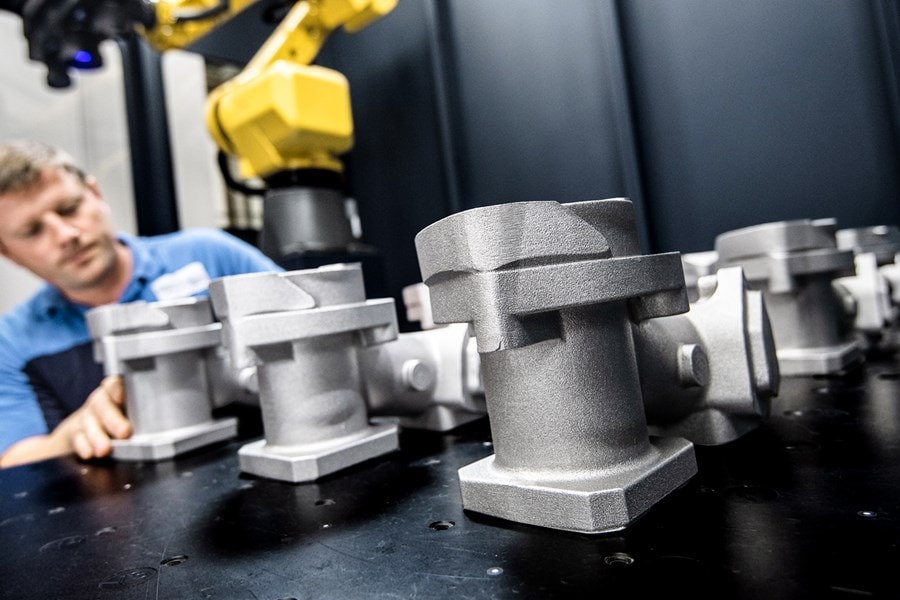

Quality Assurance in Series Production

ZEISS ScanBox Series 5 optimizes your series inspection and supports you in checking your production processes. The powerful 3D measuring machine provides you with full-field measuring results for CAD comparison in a very short time, visualizes possible deviations from GD&T and accelerates your production, maintenance and repair processes. Use the system for fast acquisition of specific measurement features and geometries, such as surface and edge points, holes or bores. Standardized and automated procedures increase throughput of parts and reduce scrap. The ZEISS ScanBox Series 5 systems allow for high process reliability during operation thanks to trend analyses in real time. Changes within the production can thus be identified quickly.

ZEISS ScanBox 5110

Measurement and inspection of parts, such as complex airfoils, up to 1000 mm in size

ZEISS ScanBox 5120

Measurement and inspection of parts, such as interior components of vehicles, up to 2000 mm in size

ZEISS ScanBox 5130

Measurement and inspection of sheet metal parts, assemblies, cast parts and turbine components up to 3000 mm in size

ZEISS ScanBox Series 5: versatile and flexible

Ergonomic Functions

The new, flexible user interface offers various ergonomic functions to support the user. A swivel arm integrated into the electronic switch cabinet can be set to the desired position, allowing the ZEISS ScanBox Series 5 system to be operated while standing or sitting.

Customized for Airfoil Inspections

ZEISS ScanBox 5110 is predestined for inspecting airfoils. Developed for gas turbine industries, ATOS 5 for Airfoil with its optimized working distance and measuring areas from 100 x 70 mm² delivers high-precision 3D data of the smallest details. You can measure a complete blisk in less than an hour. A turbine blade is inspected within a few minutes.

Virtual Measuring Room in GOM Inspect Pro

The virtual measuring room (VMR) is the central control and measurement planning software for all elements of the optical measuring cells. In the VMR, the real environment, that is, robots, sensors and parts in the measuring cell, is functionally displayed in a simulation. Programming includes the kinematics of the robot paths, the fixture and the measurement plan. Thanks to the VMR, the user can work with the system without requiring specific robot programming skills. All robot movements are simulated and checked for safety before being performed in the actual environment.

Optical Serial Measurement

ZEISS ScanBox Series 5 is developed for serial measurements and is often directly used in the production environment. Measuring procedures are automated and the reproducibility of 3D measuring data of identical parts is ensured. You create the measuring programs for inspection in the virtual measuring room (VMR) of the GOM Inspect Pro software. The robot is fully controlled by the software and successively moves along the measurement positions. Changes to the data status of the CAD or the inspection plan can be quickly updated by the parametric structure of the software. During operation, workers can easily operate the system.

Virtual Clamping of Hang-on Parts

The Virtual Clamping technology eliminates multiple measurement loops for parts that are typically measured on mechanical fixtures with four support points.

- High accuracies

- Use of simple fixtures

- Great time savings

Sensor Compatibility

ATOS sensors provide full-field 3D coordinates for each individual measurement. Within a few seconds, up to 12 million independent measuring points are captured per scan. As a result, the measuring data is characterized by highly detailed reproduction, thereby enabling very small part features to be measured.

High-speed 3D scanning system for industrial applications, precise coverage of complex geometries

Precise scanning of smallest details, extremely high stability in automated applications

| ZEISS ScanBox 5110 | ZEISS ScanBox 5120 | ZEISS ScanBox 5130 | |

| Dimensions | 2200 × 3550 × 3050 mm (LC*) 2200 x 2850 x 3050 mm (D**) |

3600 × 4250 × 3050 mm (LC) 3600 x 3550 x 3050 mm (D) |

4300 x 4250 x 3050 (LC) |

| Power supply | 200–500 V (3-phase, 16 A) | 200–500 V (3-phase, 16 A) | 200–500 V (3-phase, 16 A) |

| Max. part size | Ø 1000 mm | Ø 2000 mm | Ø 3000 mm |

| Max. part weight | 2000 kg | 2000 kg | 2000 kg |

| Entry | light curtain or sliding door with safety switch | light curtain or sliding door with safety switch | light curtain |

| Opening width | 1000 mm (LC) 950 mm (D) |

2400 mm (LC) 2100 mm (D) |

3100 mm (LC) |

| Floor mounting or fixing | required | required | required |

| Loading concept | manual, crane (D) | manual, transport cart, pallet truck, crane (LC) | manual, transport cart, pallet truck, crane (LC) |

| ATOS 5 for Airfoil, ATOS 5**** | ATOS 5, ATOS 5 for Airfoil | ATOS 5 |

*LC: Light curtain

**D: Door

***The permissible application weight may be limited by the selected rotation table unit

****Verification of set-up necessary