Optical 3D measuring system brings innovation in the automotive industry

To maintain their position in a competitive market, automotive suppliers must produce high-quality products reliably and quickly – in the face of considerable price pressure. French company Forges de Courcelles, which produces crankshafts for well-known car manufacturers like Renault and Volkswagen, is responding to industry challenges in innovative ways – with support from GOM.

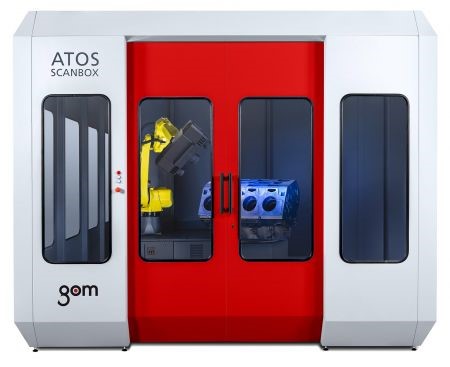

Inspection in production with ATOS

Detailed quality controls are essential to ensure zero defects in production. Forges de Courcelles therefore opted for the ATOS ScanBox, an automated optical 3D measuring machine that delivers much more data than conventional coordinate measuring machines in shorter inspection times. The company now deploys an ATOS ScanBox 5120 at three production stations. “Thanks to the machines, the fast measuring procedure, and the possibility to check three components at once, we have been able to reduce our response time for component problems and deviations from the standard process,” says Cyril Schäfer, head of R&D, who played a key role in setting up the ATOS ScanBox.

ATOS ScanBox 5120

The ATOS ScanBox 5120 can measure parts up to 2,000 mm, such as vehicle interior components. It is also used in foundry and forge applications, e.g. for inspecting castings, sand cores, and patterns.

For tiny details and grand visions

GOM developed the ATOS ScanBox specifically for production environments. The ATOS sensor delivers 3D measurement data quickly and accurately. The metrologists generate the measurement plan and evaluation offline in the virtual measuring room, the central control station and measurement planning software. The software then handles the entire process control via a special user interface designed for simplified operation and performs the measurement and inspection workflow automatically.

“Thanks to the 3D scanner, our company is able to measure the entire surface of the components we produce. This opens up new perspectives for optimizing the relationship between product and process.” Schäfer sees great potential in the ATOS technology for the development of new products.

Other optical 3D metrology systems

|

|

|

|

Bring quality, precision, speed and reliability to your production proccessAIE provides the total 3D metrology solutions from GOM to industrial customers and mechanical research institutes and universities in Vietnam. Contact us for free consultation today. |