Industrial 3D Scanning Technology

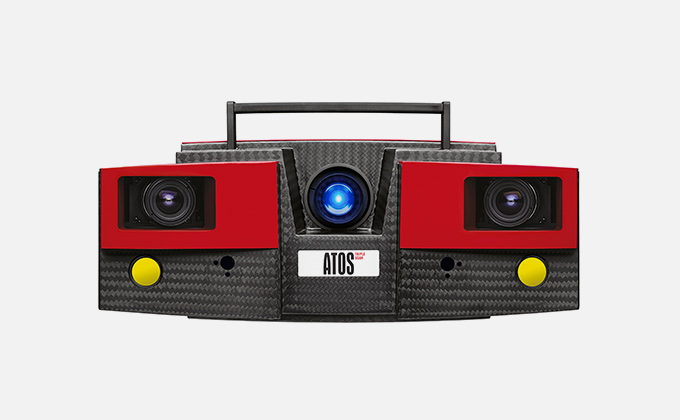

ATOS is metrology tested, aerospace certified accurate, and widely recognized as the preferred measuring tool. The ATOS series of high quality industrial structured blue light 3D scanners provide precision scans with detailed resolution at high speeds.

It is a type of a coordinate measuring machine CMM that utilizes optical non-contact technology to capture millions of accurate points in a single fast scan.

ATOS solutions are used in many industries for the inspection of parts such as sheet metals, tools and dies, turbine blades, prototypes and injection-molded and pressure die-cast parts.

ATOS CORE

Small to medium parts. Entry level system.

ATOS Core provides 3D coordinate measuring data for 3D printing, reverse engineering, inspection and adaptive manufacturing. It serves as mobile measuring device and stationary desktop scanner as well supports automation processes within the ATOS ScanBox

outstanding features

In a comparison to a traditional coordinate measuring machine (CMM), which takes a single measurement at each programmed point where the probe contacts the surface of the part, or an industrial 3D laser scanner that gathers measurement in strips or lines of data, ATOS is an optical non-contact measuring system that captures full-field scans of a volumetric area collecting millions of points per scan.

ATOS setup is minimal and each measurement can take less than 1 second. It does not require specialized programming skills or highly accurate fixtures. ATOS discovers discreet problematic areas that would have been undetected by traditional measurement methods by quickly scanning the entire object (part, mold, tool, die, etc.) in an accurate and dense point cloud.

This digital 3D blue print of the object’s geometry is then compared to CAD with a 3D inspection color map displaying a spectrum of colors that signify areas in and/or out of tolerance.

The 3D color map takes the uncertainty away so the optimal corrective action can be applied eliminating iterations and saving an enormous amount of costs and time that were once being spent on rework.

- Highly accurate traceable 3D measurements

- Detailed high resolution scans

- Quick data collection

- Advanced parametric inspection functionality

- Complete metrology solution for dimensional analysis (GD&T, trend analysis, industry specific inspection functionality, and much more…)

- Comprehensive reporting