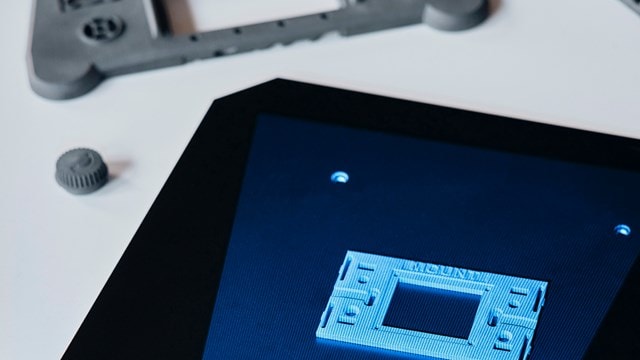

SCAN 1 – COMPACT, PRECISION 3D SCANNER

Scan 1 was born to serve new tasks and is the optimal solution for basic measurement needs, especially in the field of mechanical research and development. Made in Germany (GOM – Brand of Carl Zeiss Group).

Advantages: Reasonable investment cost, easy to use, fast scanning speed

Application: Molding industry, plastic injection, consumer electronics, footwear