2020 Ultimate Guide to Metal 3D Printers

In this guide, our industry experts will help you cut through the noise by breaking down the real benefits of metal 3D printing, what technologies and materials are out there, and how you can take the first steps in adopting metal 3D printing in your own facility.

Topics covered in the guide include:

- Metal 3D printers vs traditional manufacturing: ROI and technical benefits

- Main spaces disrupted by metal 3D printing

- Metal materials available for 3D printing today (and likely to exist in the future)

- 4 types of 3D metal printers and their pro’s and con’s

3D print strong partsMarkforged specializes in 3D printers for high-strength applications. Our range of metal and composite 3D printers yields parts in stainless steel, tool steel, carbon fiber, fiberglass, inconel, titanium, and more. |

|

|

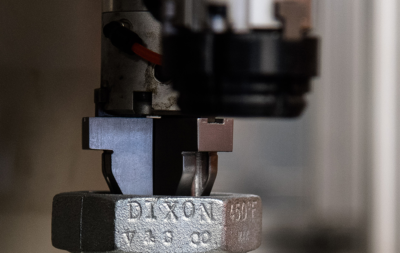

Open up CNC bandwidth for revenue-generating partsLean Machine now has 5x lower use of in-house CNCs for tooling and fixtures, using Markforged technology to create parts that can’t be achieved by other processes. The CNC operators now run the machines full time purely for production work instead, with fewer interruptions from Engineering |

Minimize lead time from

prototype to production part

With an in-house Markforged 3D printer, you are in greater control of when your parts are made, reducing the risk of unexpected supply chain delays.

Unlock design freedom and 3D print geometrically complex parts

3D print parts that were previously too complex or costly to machine. By adopting Markforged, Stanley Black & Decker consolidated a four-piece assembly into one 3D printed part that otherwise could not have been made without assembly.