UnionTech’s 3D printing solution for the footwear industry empowers a shoe mould factory in southern China

In an era of intelligent manufacturing, digitalization, intelligence, and IoT have become the overwhelming tendency of all industries across the world, transforming the industries from simple mechanical production lines to intelligent terminals, the frontiers in digitalization.

While the mold industry is embracing interconnection, the advantages of digital production solutions have emerged. UnionTech and Huifeng jointly developed a professional digital solution for the shoe mold industry, accelerating the digital transformation of Huifeng in its shoe mold manufacturing business.

Digitalization has created momentum for the shoe mold industry

“In 2020, we purchased ten UnionTech FL600HD 3D shoe mold printers and equipped them with the UnionFab cloud platform management system. With UnionTech’s digital solution, our cost has been reduced by 40%, and the production efficiency has increased by 60%. This ushered in a new era of innovative digital manufacturing process for Huifeng.” – Mr. Luo Haijun, Production Manager, Guangdong Huifeng Mold Co., Ltd.

Phase out Traditional Manufacturing Process to Address New Challenges

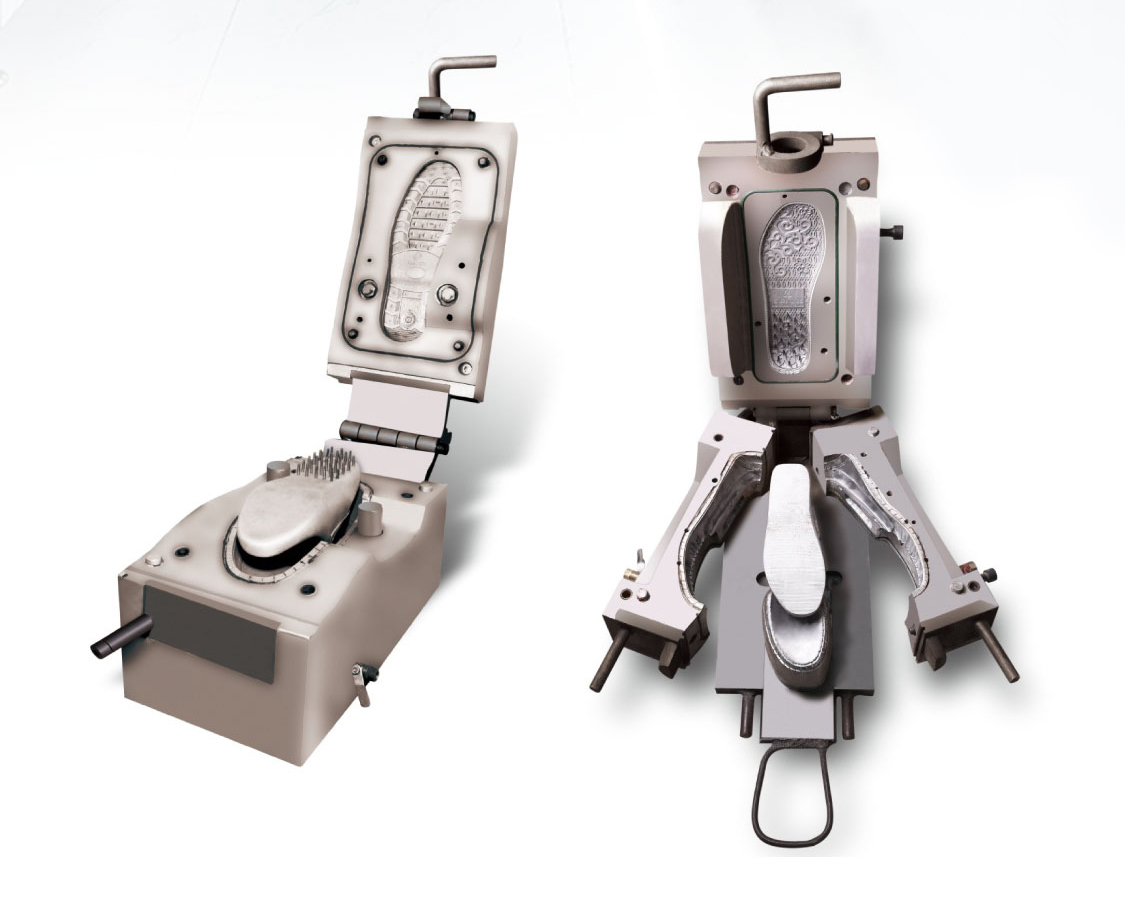

The shoe manufacturing industry is complicated and labor-intensive. The manufacturing of the sole molds alone involves a number of steps, such as wooden mold processing, silicone overmolding, plaster molding, mold casting, chemical corrosion and texturing, etc. The advent of 3D printing technology has ushered in a new era for the shoe manufacturing industry. Whether it is the manufacturing of shoe molds, or the direct manufacturing of soles, uppers and other shoe components, all can benefit from 3D printing technology, which streamlines the manufacturing process, allows more efficient design iteration, and adds more dimensions to the product design and innovation.

The traditional manufacturing process of shoe molds is expensive and time-consuming, yet it usually delivers unsatisfactory accuracy. Moreover, some procedures like texturing can cause severe pollution to the environment. As an important procedure in the rapid shoe customization chain, 3D printing has attracted increasing attention from shoe manufacturers. Not only does 3D printing bring mold-free and small-batch customization capabilities to shoe manufacturers, but with the help of other digital technologies such as digital design and 3D scanning, it also allows small-scale and decentralized manufacturing of shoe molds, which is substantial progress compared to the traditional manufacturing process.

Against this backdrop, the production management team of Huifeng realized that the mediocre traditional manufacturing processes must be phased out in order to unlock business improvements.

This shoe mold manufacturer has fully digitalized its manufacturing process

In 2020, Huifeng purchased ten UnionTech FL600HD 3D shoe mold printers and equipped them with the UnionFab cloud platform management system. With UnionTech’s digital solution, Huifeng saw a cost reduction of 40% and an increase in production efficiency of 60%. This ushered in a new era of innovative digital manufacturing process for Huifeng.

3D printing technology is the inevitable result when information technology and digital technology find their way into the traditional manufacturing industry. Saying goodbye to traditional wooden molds, this innovative manufacturing process is more intelligent, automated, efficient, precise, and flexible, while the overall cost is lower. Luo Haijun, production manager of Huifeng, said that UnionTech’s digital solution for 3D shoe mold printing offers a myriad of advantages, such as shorter production cycle, lower risk in molding, lower manufacturing cost, more friendly to the environment, more energy-saving, and lower labor cost, etc. He forecast that 3D printing solutions will completely replace the traditional manufacturing process using wooden molds in the next 3 to 5 years. He added that Huifeng will pay close attention to UnionTech’s development plan for the shoe manufacturing industry, and is expecting UnionTech’s new 3D printing products.

UnionFab, a SaaS Cloud Platform for 3D Printing Manufacturing

UnionFab is a SaaS cloud platform for 3D printing manufacturing which helps manufacturers to complete intelligent upgrades quickly and cost-effectively. Its functions, including order management system, data assistance, intelligent production scheduling, remote production management, digital equipment management, etc., improve the service experience, production efficiency, and business management of enterprise customers. With the UnionFab cloud platform management system, Huifeng found their labor cost greatly reduced. Among UnionFab’s various functions, they think intelligent production scheduling and remote production management are extremely beneficial.

Powered by its full value chain coverage with advanced digital solutions of “software + hardware + service”, UnionTech has successfully delivered a wide range of digital solutions for industries both at home and abroad together with its partners, translating to extensive practical experience in digital transformation.

“Innovation, one of the driving forces behind our progress, helps us achieve our goal to exceed customer expectations.

Huifeng is always dedicated to the niche market of slipper molds. We have been concentrating on research and development in this field and actively exploring innovative ideas. The adoption of the advanced 3D printing manufacturing process has enabled us to provide our customers with more professional products and services.” – Mr. Huang Liefeng, General Manager, Guangdong Huifeng Mold Co., Ltd.

With extensive experience in the shoe mold industry, UnionTech offers products and services that meet international standards, powering our customers in China’s shoe mold industry to upgrade to high-end manufacturers. It is our dream to witness the progress of China’s digital intelligent manufacturing together with our customers. We will continue to work with industry giants and create one-stop 3D printing solutions for our customers, prompting the development of the shoe mold industry with innovative digitalization ideas.

About Huifeng

Founded in 1998, Guangdong Huifeng Mold Co., Ltd. is a Jieyang-based mold manufacturer specializing in slipper molds that integrates R&D, production, and sales. Located in an area of over 8,000 square meters with modernized standard workshops and office buildings, it produces a variety of slipper molds, such as blowing mold, crystal mold, double-color mold, EVA mold, etc. Powered by its R&D and design departments, its full range of production lines, including 3D scanning, CNC, 3D printing, molding, processing, machining, texturing, and injection, have reached an annual production capacity of over 20,000 pairs.

________________________________________________________________

AIE is a partner of Uniontech in Vietnam. Contact us if you have any questions!